Specifying Specialty Steel Doors

Published in Doors & Hardware Magazine

Whether protecting building occupants from tornados, forced entry, or elementary school band practice, specialty doors are utilized in the most demanding environments. They are available in a variety of materials, but steel has long been the benchmark for performance and longevity, particularly in settings where sound reduction, or resistance to fire, blasts, or windstorms are important.

These doors are expected to perform flawlessly, and in many cases, occupants’ lives depend on it. The first step to ensuring reliability is proper specification. In this article, we’ll look at four of the most popular types of specialty steel doors, their uses, and tips for specifying each one.

Acoustic

Acoustical door assemblies (ie. door, frame, hardware, and seals) are engineered to prevent a specific amount of sound from passing through the door opening. Steel is the optimum material for this purpose. Although these assemblies have been used in music studios for decades, they are becoming more common in meeting rooms, hotels, government buildings, and buildings located near airports and highways. As studies continue to show that benefits of a quieter workplace include higher productivity, less sick time, and higher employee retention, acoustically rated door systems are growing increasingly popular in office buildings as well.

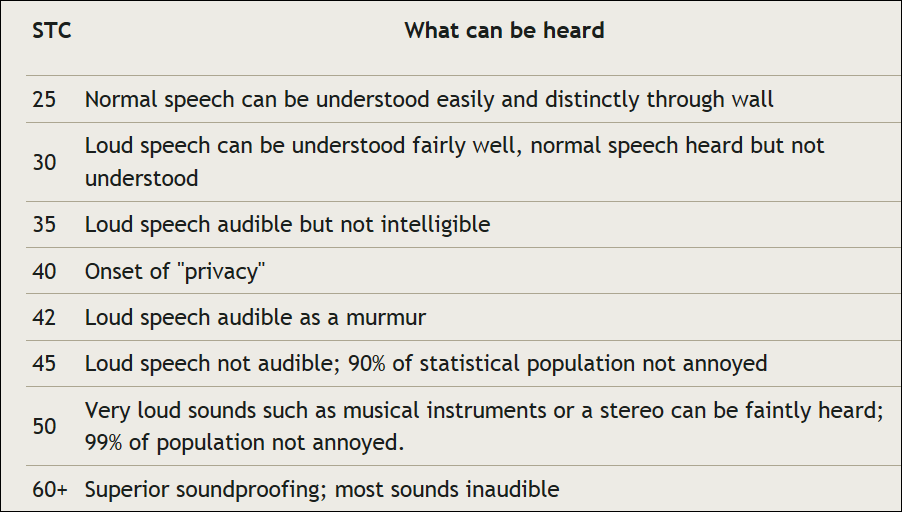

Two of the most critical factors to understand when specifying acoustic doors are the Sound Transmission Class, or STC rating, and the Outdoor-Indoor Transmission Class, or OITC rating. The STC rating is calculated in accordance with ASTM E413 and provides a single number rating for interior building partitions that are subjected to mid to high frequency noises such as talking, TV, or office equipment. The STC scale is a logarithmic progression, which means that an increase of three points doubles the sound transmission reduction.

The OITC rating is calculated in accordance with ASTM E1332. It provides a single number rating for the sound transmission from the external environment into the building envelope of low to mid frequency noises such as rail and vehicular traffic. As with the STC rating, the higher the number, the better the noise isolation.

A common mistake is to over-specify acoustic doors, particularly in settings where the intent is simply to suppress the sounds of people or equipment from room to room. Standard steel doors often have an STC rating in the 25-35 range. Specifying a door with an STC rating in the 40s is adequate in most situations, but in settings where sound control is critical, such as an office where confidential meetings are held, doors above STC 45 may be needed. For these, it is recommended to work with an acoustic consultant.

When completing the specification, be sure to include the required STC and OITC values. Note that doors with STC ratings above 35 should not be included in Spec Sections for standard or custom doors and frames. They should be specified as special assemblies warranting closer attention to details such as hardware, seals, and installation.

Blast Resistant

Blast resistant door assemblies are designed to protect people and property from detonations resulting from high explosives, vapor clouds, fine dust clouds, chemical reactions, and more. They are typically specified for buildings where security is a major concern or where an explosive event would be possible, such as military bases, government offices, and industrial facilities.

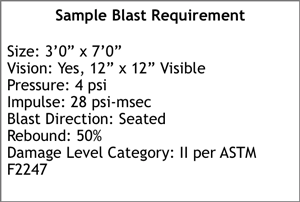

Specifiers will need to work with a blast consultant to determine the following:

- Blast pressure: The maximum pressure (psi) expected to be exerted on the assembly by the projected blast event.

- Blast duration: The length of time (milliseconds) required for the blast pressure to decay to zero.

- Blast impulse: The blast energy as described by the area under the pressure vs. time curve (measured in pressure-time units such as psi-msec).

- Blast direction: The direction of the blast load relative to the door assembly.

- Rebound: The percentage of the initial peak blast pressure that is reflected back to the blast resistant unit.

Required response: The acceptable level of damage that would result from the projected blast event on a door assembly. The responses range from Category I (no damage) to Category V (catastrophic failure).

Bullet Resistant Assemblies

Bullet resistant assemblies are typically installed in government buildings, cashier stands, high crime rate areas and any structure where increased safety is desired. A security consultant should analyze the building conditions to determine the proper bullet resistance level required.

Whoever commissions the project will likely determine what standard should be specified, but UL 752 is the most common test method. It assigns a level from 1-10, with 10 being the highest level of resistance to gunfire. Steel doors are generally available up to level 8.

A variety of cores can be bullet resistant, such as steel stiffened, honeycomb and polystyrene. Therefore it is only necessary to specify a UL 752 level and not a specific core material, particularly at the higher levels as many of the cores are proprietary.

Tornado

The United States averages around 1,200 tornadoes every year. Most tornadoes wreak havoc in “Tornado Alley”, which runs from Texas up through Oklahoma, Kansas, Nebraska, and into Iowa. These incredibly powerful storms can destroy standard door assemblies, leaving buildings and occupants vulnerable to intense winds and flying debris.

Tornado-tested assemblies are proven to withstand storm pressures, wind, and debris. Design professionals will need to ensure the products they select are permitted on the shelter being designed. Tornado door components should never be mixed and matched because they are tested and installed as an assembly – including hinges, door, frame, anchors, latching hardware.

FEMA P-361 outlines the criteria for the design and construction of community shelters and residential safe rooms that will provide protection during tornado and hurricane events. Steel is the most prevalent door material to pass FEMA P-361. No wood door commercially available today, with or without metal sheathing, has successfully passed FEMA P-361. Aluminum and fiberglass doors are not currently listed for tornado resistance without internal steel plating.

Quality is Key

Proper specification is only the first step to ensuring an effective specialty door solution. Finding a quality product is also a crucial part of the process, particularly when it comes to steel specialty doors that play a vital role in maintaining the life safety of building occupants. In an effort to help architects and specifiers ensure these products consistently meet quality standards, the Steel Door Institute has developed a new industry certification – SDI Certified. Manufacturers who hold this certification are regularly audited to ensure they meet rigorous manufacturing, performance, and quality standards. By specifying SDI Certified, design professionals can be confident the products will meet the highest standards in the industry.

Specialty doors often look just like standard doors.