Specifying Frames to be Water Resistant

Steel frames that are not specified correctly may result in water damaging the interior of a building over the course of years, months, or even weeks. The purpose of this article is to explain how to ensure your frames are water resistant to “normal” rainfall activity, not the extreme windstorm flooding of super storms like Sandy and Katrina.

Water Proof or Water Resistant?

Too many factors come into play such as building location, the position of the frame, or even architectural aesthetics, for manufacturers to guarantee that a frame is 100% waterproof. However, steel frames can be made adequately water resistant if designed and installed correctly with the proper materials.

Here are important tips to ensure the steel frames you specify are as water resistant as possible:

Installation Relative to Wall Face

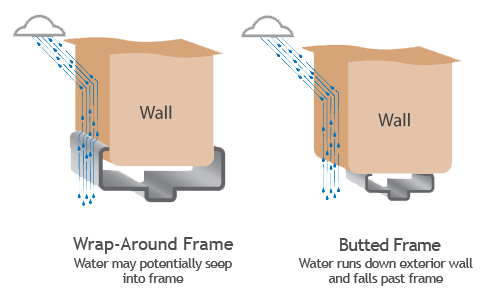

A critical design factor is the position of the assembly relative to the exterior wall face. It is highly recommended that frames be installed with a set-back of at least a brick width from the exterior face of the wall. This set-back minimizes the potential for “capillary action” to allow seepage into the frame and also minimizes direct dripping of water from the wall surface onto or into the door, frame, or glazing.

“Wrap-around” frames or frames mounted flush with the exterior wall surface are not recommended for exterior walls.

Continuously Welded

Some specifications simply state “welded frames” and not whether they’re specifying face welds or continuous full profile welds. This often results in a face welded frame being supplied due to the additional labor cost of continuous full profile welds. Despite the incremental cost difference, continuous full profile welds for exterior openings reduce the likelihood of water leakage since the two pieces of the frame have been fully bonded.

The more economical and readily available face welded frames can still be made water resistant by the application of caulking or sealant to the inside of corner joints and outside of intersections prior to installation by the appropriate jobsite personnel. Overall, continuous welds are a slightly safer option than face welds as they do not have to rely on sealants that may crack over time.

Glazing

Glazing and glazing beads should be located on the exterior side of the frame so water doesn’t pool on the stop or soffit — it should just roll right off the window. The sealant applied to both sides of the glazing is usually sufficient to prevent leakage around the perimeter of glazing. Tamper resistant screw heads can also be specified if security is a concern.

Weather Stripping

Important components for assuring weather resistance of the door opening are the perimeter weather strips, gaskets, and thresholds. The Steel Door Institute Technical Data SDI 111-E shows the variety of designs available from weather strip manufacturers.

Operational forces and threshold heights are strictly limited due to recent accessibility, means of egress, and handicap regulations. Most weather strip manufacturers have conducted extensive water penetration and operational tests and should be consulted for guidance.

Special Considerations For Frame Profiles

An advantage of using steel frames is the ability to fabricate special profiles at all or some of the components. With this in mind, it is possible to fabricate top surfaces of horizontal members (at extra cost/time) with a slope to promote water run-off.

Summary

While no one can promise a frame will be waterproof, following these suggestions will ensure your steel frames are as water resistant as possible.