ASTM E119

Standard Test Methods for Fire Tests of Building Construction & Materials

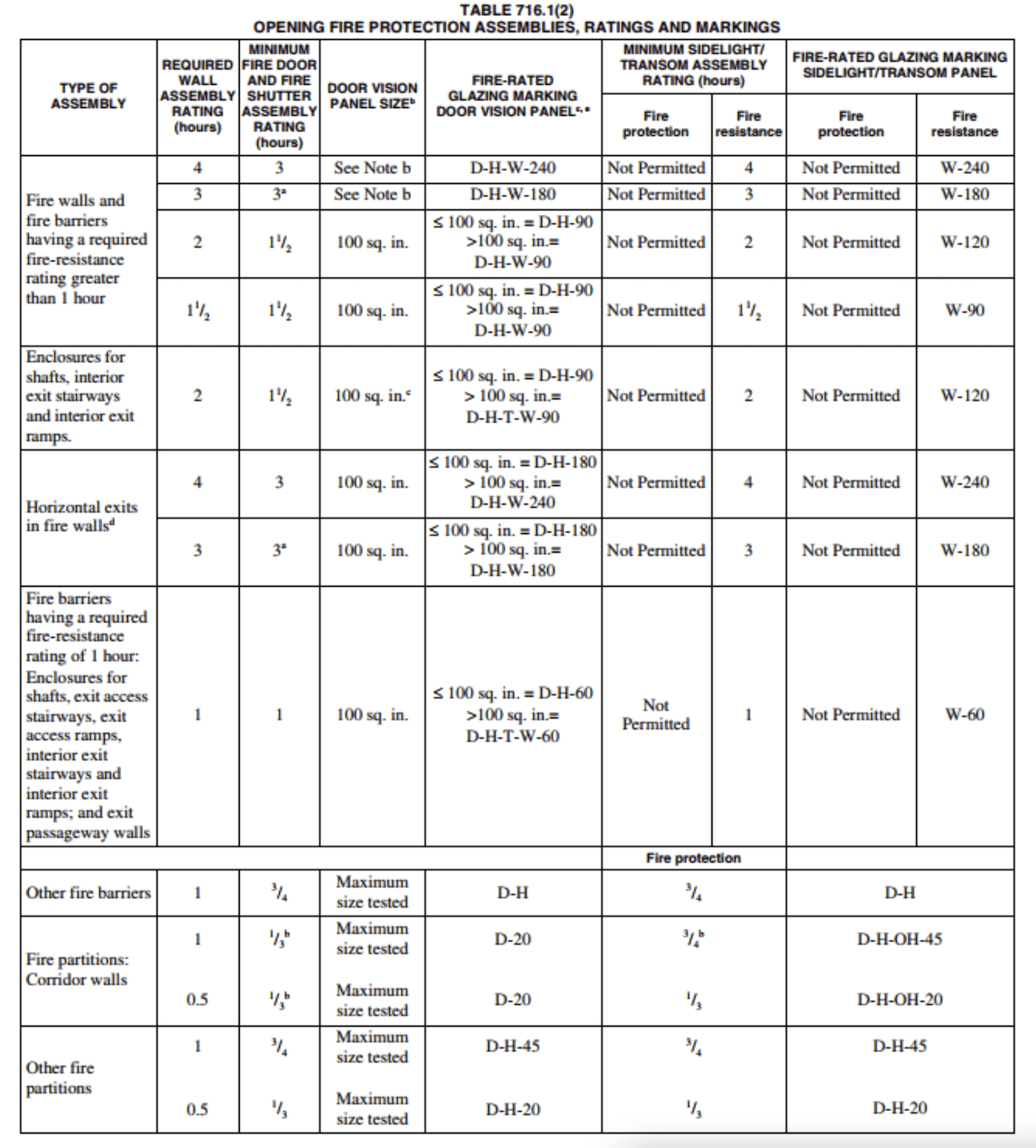

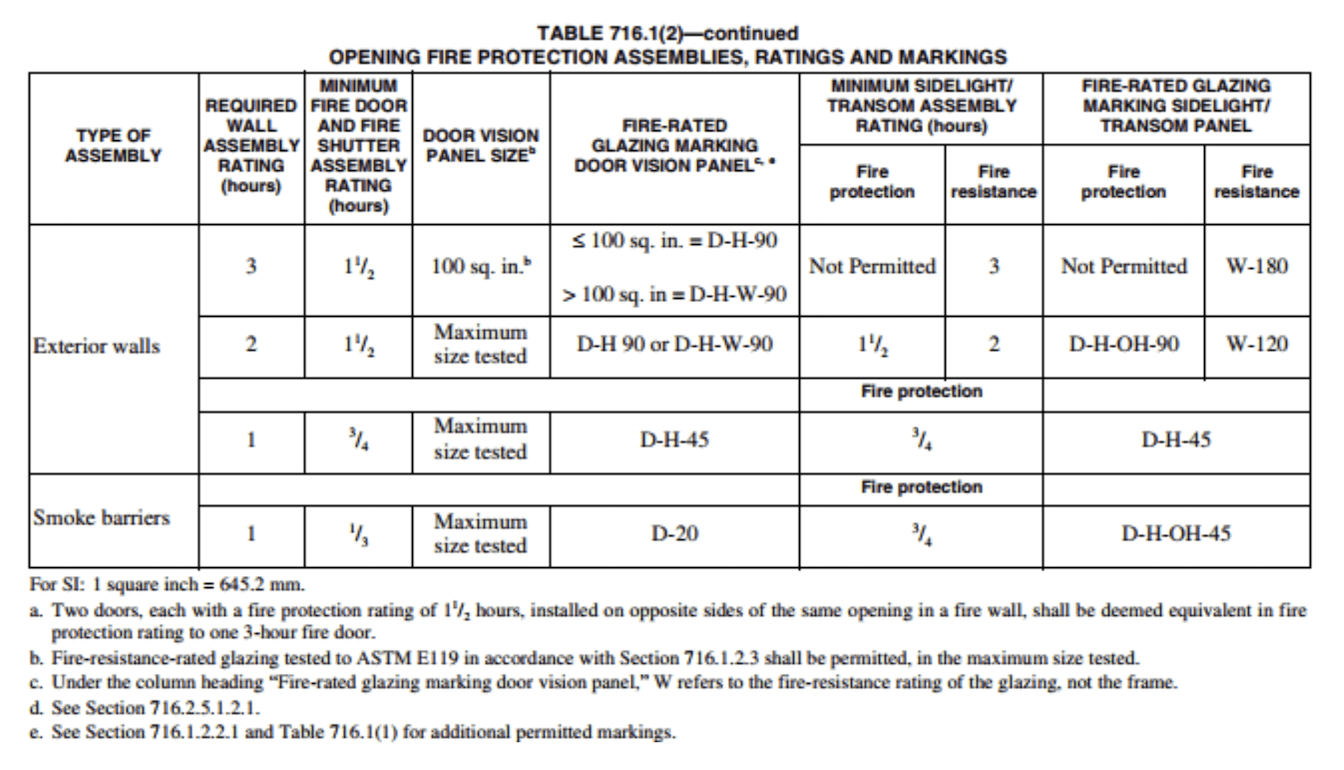

The International Building Code® (IBC) requires any frame fire rated for one hour and greater and incorporating glazing to be tested and certified as a fire resistive assembly. This requirement was first included in the 2009 Edition of the IBC and has been clarified in subsequent editions with the use of tables, such as the one from the 2018 edition of the IBC shown at the end of this article.

The terms fire resistive and fire protective appear to be similar; however, they are very different. We typically use and are much more familiar with fire protective products. Fire protective and fire resistive assemblies each contain the spread of fire. Fire resistive assemblies must also meet an average 250°F temperature rise rating above the initial temperature for all thermocouples measuring temperature on the unexposed surface, and also a maximum of 325°F for any single thermocouple on the assembly.

This temperature rise rating is for the duration of the rating period. As an example, at the end of a one-hour fire test, the temperature rise on the surface of the glass and frame not exposed to the test furnace can be no more than 250°F.

Fire resistive assemblies also cannot have any flaming on the unexposed surface or develop any opening through the assembly during the fire endurance or hose stream tests.

Fire window frames are tested to UL 9 or NFPA 257. Fire resistive assemblies with glass are tested to UL 263 or ASTM E-119, the test methods used to test fire resistive building materials and constructions. Fire protective assemblies or fire window frames have size restrictions. Fire resistive assemblies with glass do not have similar size restrictions because they are tested as a wall to ASTM E-119 or UL263.

A fire resistive assembly with glass is tested using the same criteria as a fire resistive gypsum or masonry wall.

For this reason, the listing is written in the same manner. The listing describes all the individual items that make up the certified assembly. As a result, an installation of a fire resistive assembly must incorporate the same items detailed in the listing. There can be no substitution of items, or methods not described in the listing unless alternatives are fully described in the published fire resistive design for the assembly. It should be noted too that the certification agency may or may not publish in their publicly available certification directories the full details of the manufacturer’s complete listing. The manufacturer and the Certification Agency’s online directory information should be consulted if alternate materials or methods are desired.

Another item to be noted in the table below applies to doors. Doors are tested and listed to UL 10C and those rated 1 hour and greater with an area greater than 100 square inches require glazing that is fire resistive and has been tested or evaluated to UL 10C in addition to the ASTM E-119/UL 263 requirements. If the glass area is 100 square inches or less, the glass is only required to be fire protective as tested in accordance with UL 10C but is also permitted to be fire resistive rated glazing when also tested to UL 10C.

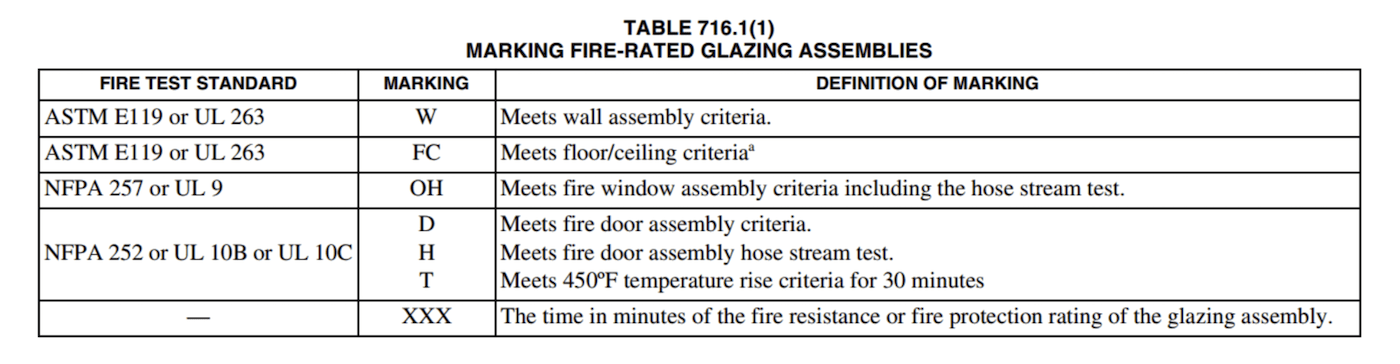

The hourly ratings of fire resistive assemblies with glass are the same as walls and have the same definitions as walls in the IBC which is typically 60 minutes (1 hr.) or 120 minutes (2 hr.). Listed fire resistive glass is identified with W and the corresponding hour rating, W-120 is an example for a 2-hour rating. Glass for a door would commonly be identified as D-W-H-90 for a 90-minute fire rated door. These glazing markings are required by the IBC and are to be permanently marked on the glazing by the glazing manufacturer.

Markings for Fire Resistive and Fire Protective Glass