Common Field Issues Affecting Fire Doors & Frames

By Justin Hendricks, Intertek

Over the course of their life cycle, fire door and frame assemblies will be subjected to varying degrees of wear and tear through everyday use. Changes in technology, such as the incorporation of electrified hardware and access control systems, as well as changing aesthetics can lead to renovation work within a building that may also require modifications to be made to door and frame assemblies on site. NFPA 80 contains published guidelines for allowable job site preparations, field modification procedures, and information on inspection requirements and repairs. This document serves as the governing standard for the installation and maintenance of fire doors, frames and hardware and is referenced in the International Building Code (IBC).

Care & Maintenance

A care and maintenance section for opening protectives was incorporated within NFPA 80 decades ago; however, it was expanded within the 2007 version and has been growing ever since. While most of the care and maintenance guidelines throughout the 1990s were relatively vague, the 1999 version of NFPA 80 did see the incorporation of repair guidelines for holes left in fire doors or frames due to changes or removal of hardware or plant-ons.

The 2007 version of NFPA 80 incorporated significant changes pertaining to the care and maintenance of opening protectives, which included the requirement for annual fire door inspections, the development of visual inspection criteria (originally eleven points for swinging doors with builders’ hardware), a procedure for field modifications made to the door or frame, and simplified bottom clearance requirements for door assemblies. Over time, new tested and listed products have emerged in the marketplace to address a variety of non-conformities related to the visual inspection criteria found in NFPA 80 and the emergence of these annual fire door inspections being regularly enforced.

While annual fire door inspections have been required by NFPA 80 since 2007, many jurisdictions had not fully enforced this until many years later because the newer code and standard versions had not yet been adopted in their region. On January 1st, 2018, the Centers for Medicare and Medicaid Services required full compliance with the annual inspection requirement found in the 2010 version of NFPA 80 for healthcare occupancies. This led to a considerable number of non-conformities being discovered in the field that ranged from door/frame clearance issues, open holes/breaks in doors and frames, missing or broken door/frame/hardware components, and door assemblies that subsequently did not operate properly. All of these issues, which had likely been present for years, jeopardize the safety of the building occupants as well as put the building at risk for increased property loss in the event of a fire.

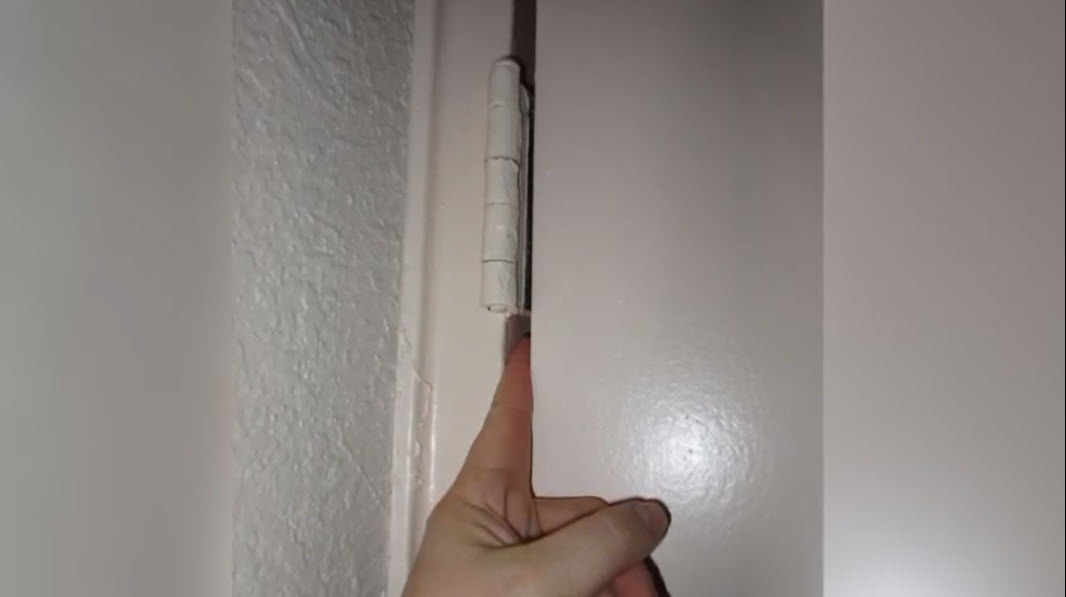

Proper Fire Door Clearance

Excessive clearance issues found on fire door and frame assemblies can lead to a myriad of issues related to fire and smoke protection. Excessive clearances near the latch area can lead to issues with latch engagement. During a fire test, if the door begins to deflect stress will begin to build at the points of securement (i.e., latch(es) and hinges). If the latch engagement is less than what it should be, door deflection could lead to the latch disengaging from the strike and the door then opening during a fire and allowing the passage of flame from one room to the next.

Excessive clearances between a door and a door frame can also lead to issues with edge seals not performing their intended function due to a lack of engagement between the seal and the door or frame. This can affect smoke protection, fire protection (i.e., intumescent materials), or other types of environmental or acoustic gasketing that may be required or present on the door assembly. Lastly, some excessive gap conditions may result in the door not operating as intended due to one or more door edges making contact with the door frame preventing it from closing and latching properly or requiring more force to open in an egress application.

Depending on their size, quantity, and location, unused open fastener holes on doors and frames can potentially contribute to containment issues in the event of a fire by allowing the fire to breach the opening prematurely and spread throughout the building.

Repair Guidelines for Fastener Holes

As referenced above, NFPA 80 has addressed repair guidelines for unused fastener holes since 1999 although the methods of repair have expanded slightly since then. In the 2022 version of NFPA 80, this information can be found within Section 5.5.7, which states the following, “When fastener holes are left in a door or frame due to changes or removal of hardware or plant-ons, the holes shall be repaired by the following methods:

- Install steel fasteners that completely fill the holes.

- Fill the screw or bolt holes with the same material as the door or frame.

- Fill holes with material listed for this use and installed in accordance with the manufacturer’s procedures.”

For holes other than what is described above, Section 5.5.8 of NFPA 80 requires these to be treated as a field modification and refers to the field modification section of the standard for further guidance. Option (3) above was first added to the 2016 version of NFPA 80 based on the emergence of tested and listed products meant to repair unused fastener holes in doors and frames.

Starting with the 2016 version of NFPA 80, Section 4.8.4.2 was added to address the use of listed products meant to address excessive bottom clearance for fire doors. Due to annual fire door inspections becoming more prevalent during this time, new products were emerging in the market to specifically address excessive gap conditions, some of which were meant only for the bottom of the door while others were tested and listed for full perimeter applications.

Some types of listed products for excessive gap applications include bar-type products that are attached to the frame rabbet or door edge, gasket type products that incorporate certain types of intumescent materials, and products that wrap and extend a door edge. When searching for an applicable solution for excessive gap conditions, please remember to check the certification listing for the product to ensure that it is listed for the specific condition you have in the field and to verify any limitations and/or installation requirements for the product.

Field Modifications

For field modifications of fire doors and assemblies beyond what is allowed by NFPA 80, the laboratory with which the product being modified is listed (i.e., listing agency) shall be contacted and provided with a written or graphic description of the modification. Upon review, the listing agency will determine the proper course of action, which may include an engineering evaluation, additional testing, or replacement of the affected door or frame. A field inspection visit from the listing agency may also be required depending on the complexity and type of modification.

Certain door or frame manufacturer’s published listings may also include additional guidance, allowances, or limitations for field preparations, and as such, the door or frame manufacturer should also be contacted and consulted prior to making any modifications in the field.

Fire Rated Labels

The fire door and fire door frame certification labels will provide information pertaining to what agency certifies the product, which is identifiable by the certification mark on the label (i.e., Intertek/Warnock Hersey, UL, etc.), as well as either the manufacturer or supplier’s name, logo, or a numerical code that can be used by the listing agency to identify the manufacturer or supplier.

Modifications made to a fire door or frame outside of the job site preparations referenced in NFPA 80 and without notifying the listing agency that certifies the door or frame places the building occupants’ safety in jeopardy and risks unnecessary damage to the building in the event of a fire. Even small modifications made to door and frame assemblies may lead to fire and/or smoke spreading more rapidly through a building than it should. Keep in mind that many disasters are preventable and ensuring that a facility follows the requirements of NFPA 80 will help protect the integrity of the building and the safety of the building occupants in the event of a fire.