Full Profile Weld vs Face Welded Frames

Some specifications only state “welded frames” and not whether they want face welds or full profile welds. In instances like this where full profile welds are not requested, specifiers can expect to receive face welded frames.

Face welded frames are the default because fully welded frames would unnecessarily increase cost and lead time. Fully welded frames may be preferred for some specialty applications and you should consult with the manufacturer.

Note: Full profile welded frames are also referred to as “fully welded” or “continuously welded”.

Face Welded Frames

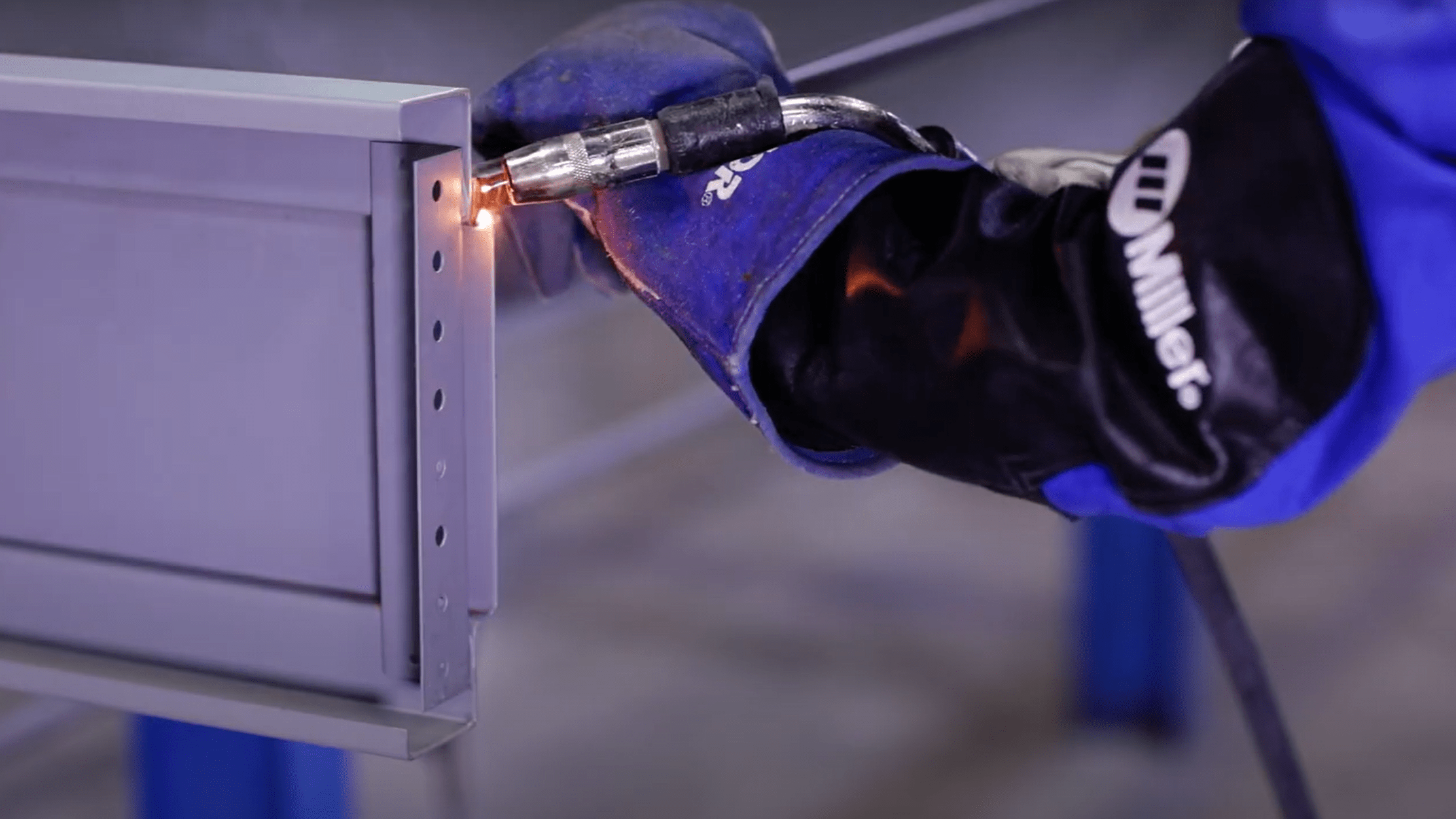

Face welded frames are specified as an aesthetic enhancement to eliminate the seams on the face of a frame. It is when the miter joint between the head and jamb face is welded on the exterior of the frame face. The weld will be ground, finished smooth, and prime painted so the seam does not show. The remaining elements of the frame profile such as the soffit, stops, and rabbets are not welded.

The water infiltration properties of a face welded frame can be improved by the application of caulking or sealant to the inside of corner joints and outside of intersections prior to installation by the appropriate jobsite personnel. Specifying face welded also provides more assurance of an accurate door opening width.

Face Weld

Full Profile Welded Frames

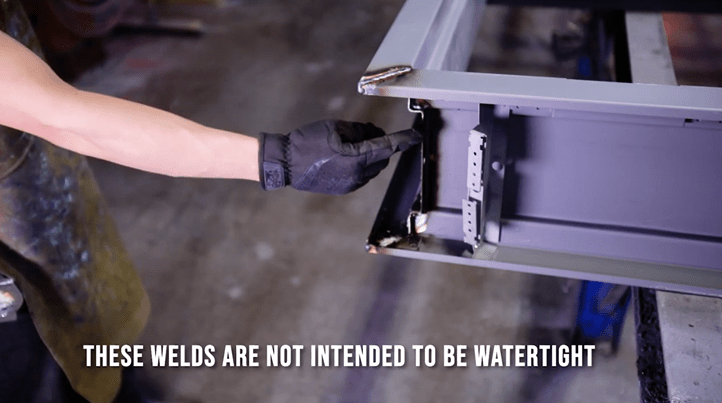

Also specified as “fully welded” or “continuously welded”, a full profile weld is when the joints between all elements of the head and jamb profiles are completely welded. The faces and returns of full profile welds may be welded internally or externally. All other frame elements are welded internally. Full profile welds are not watertight but can further reduce water infiltration.

Full Profile Weld

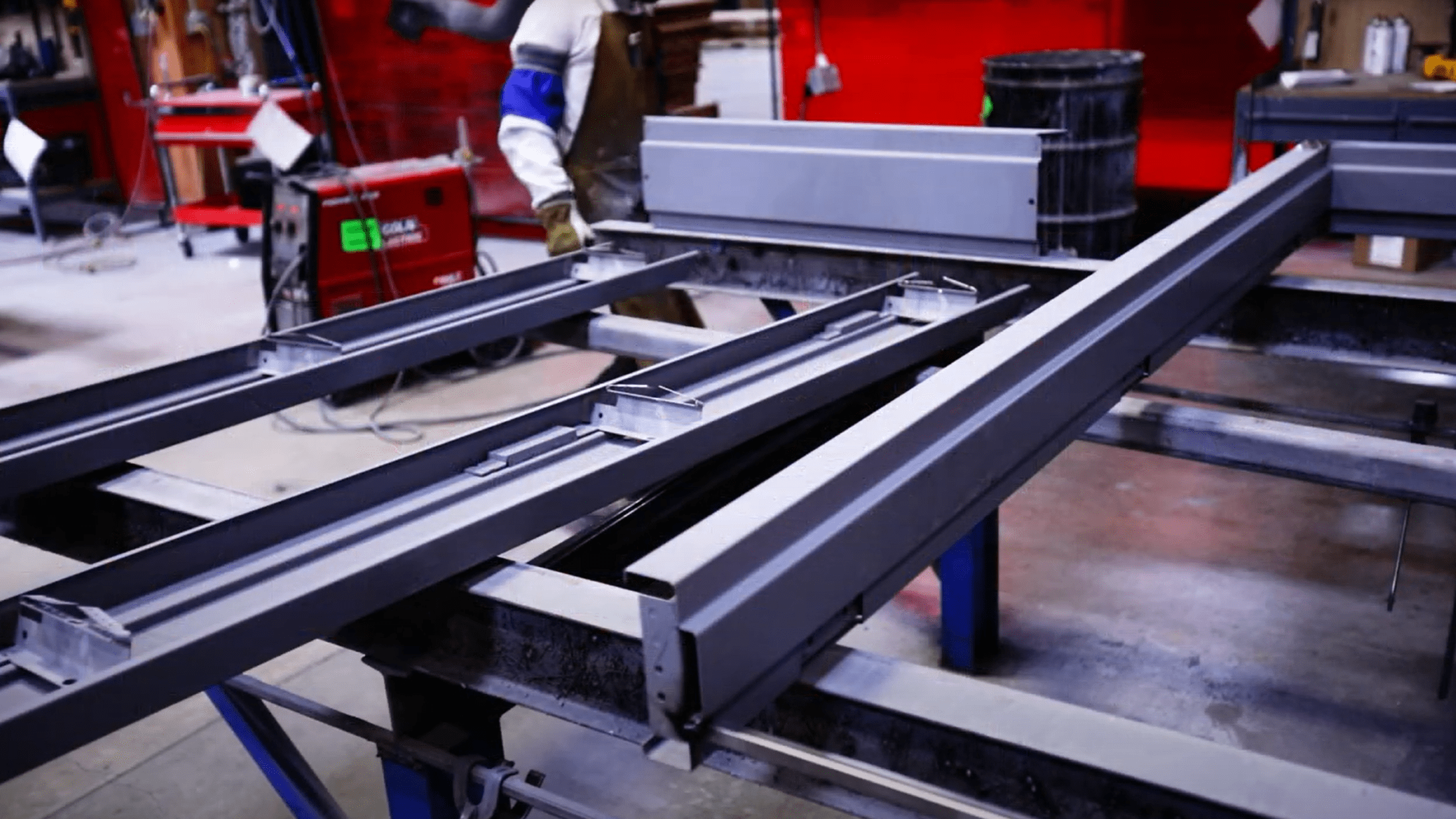

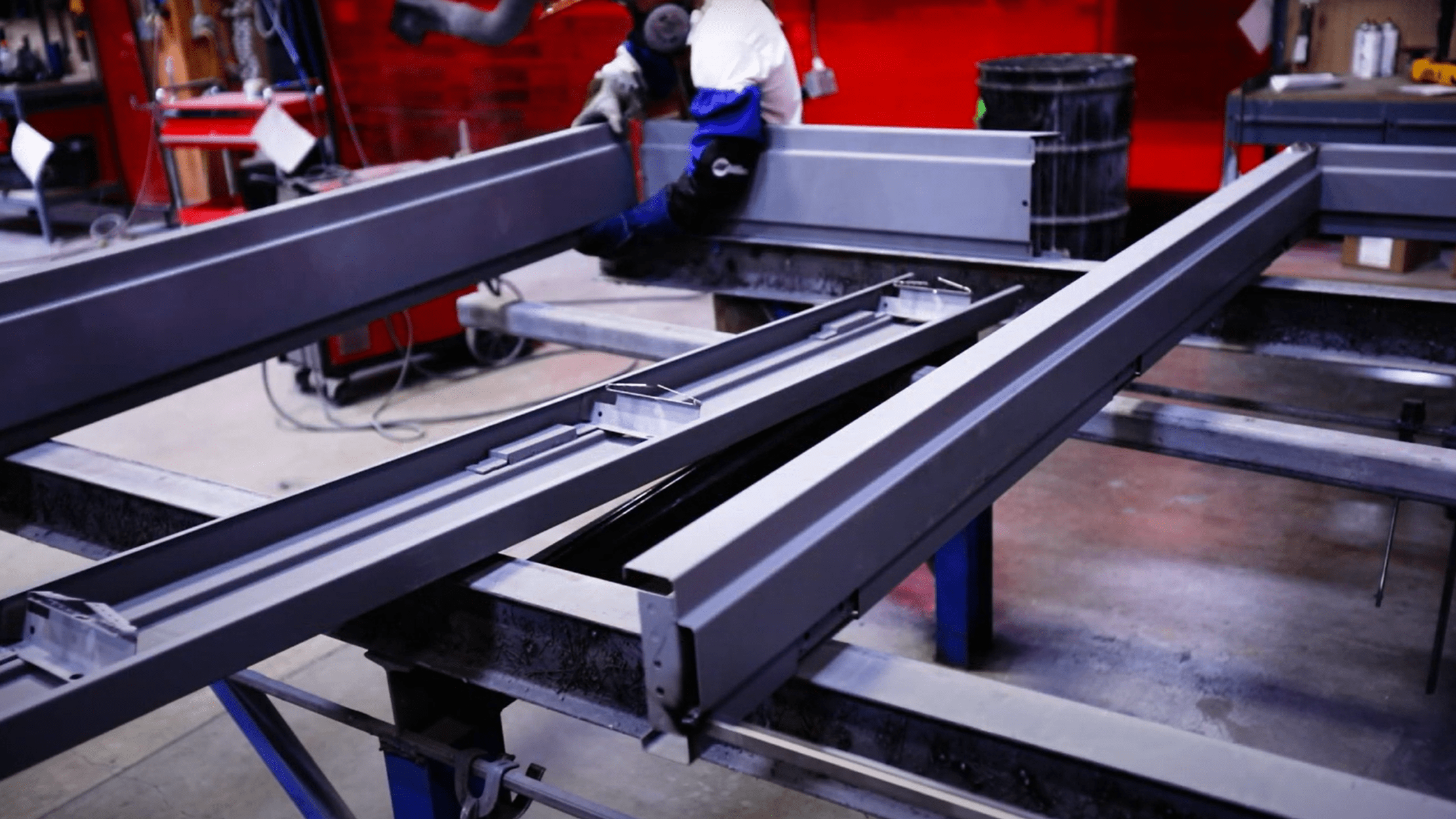

How to Prep Frames for Welding

Properly setting up the frame before welding is critical for ensuring the finished frame is square. Follow these six steps to ensure that each frame is ready for welding.

Door Frame Weld Prep - Step #1

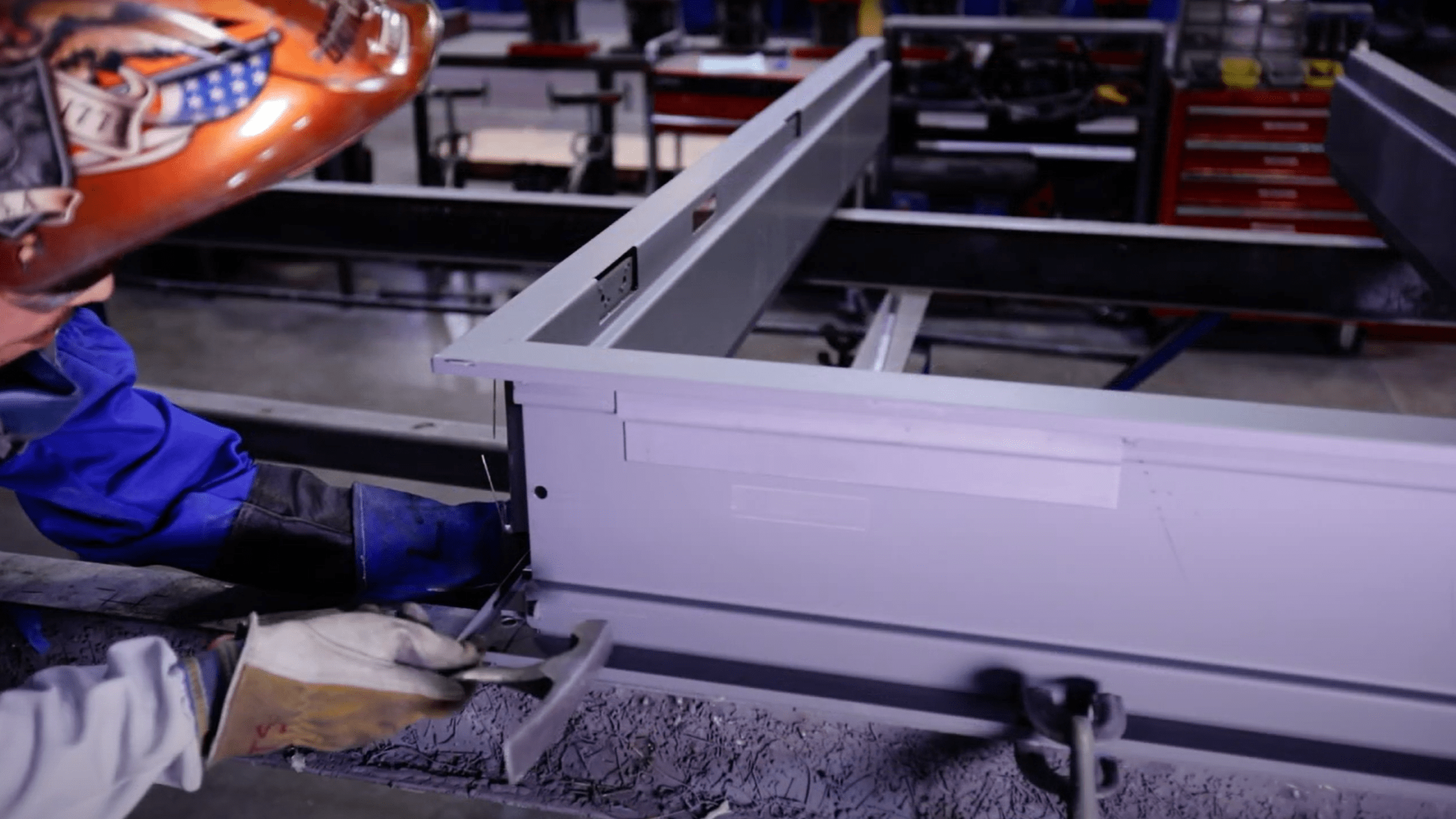

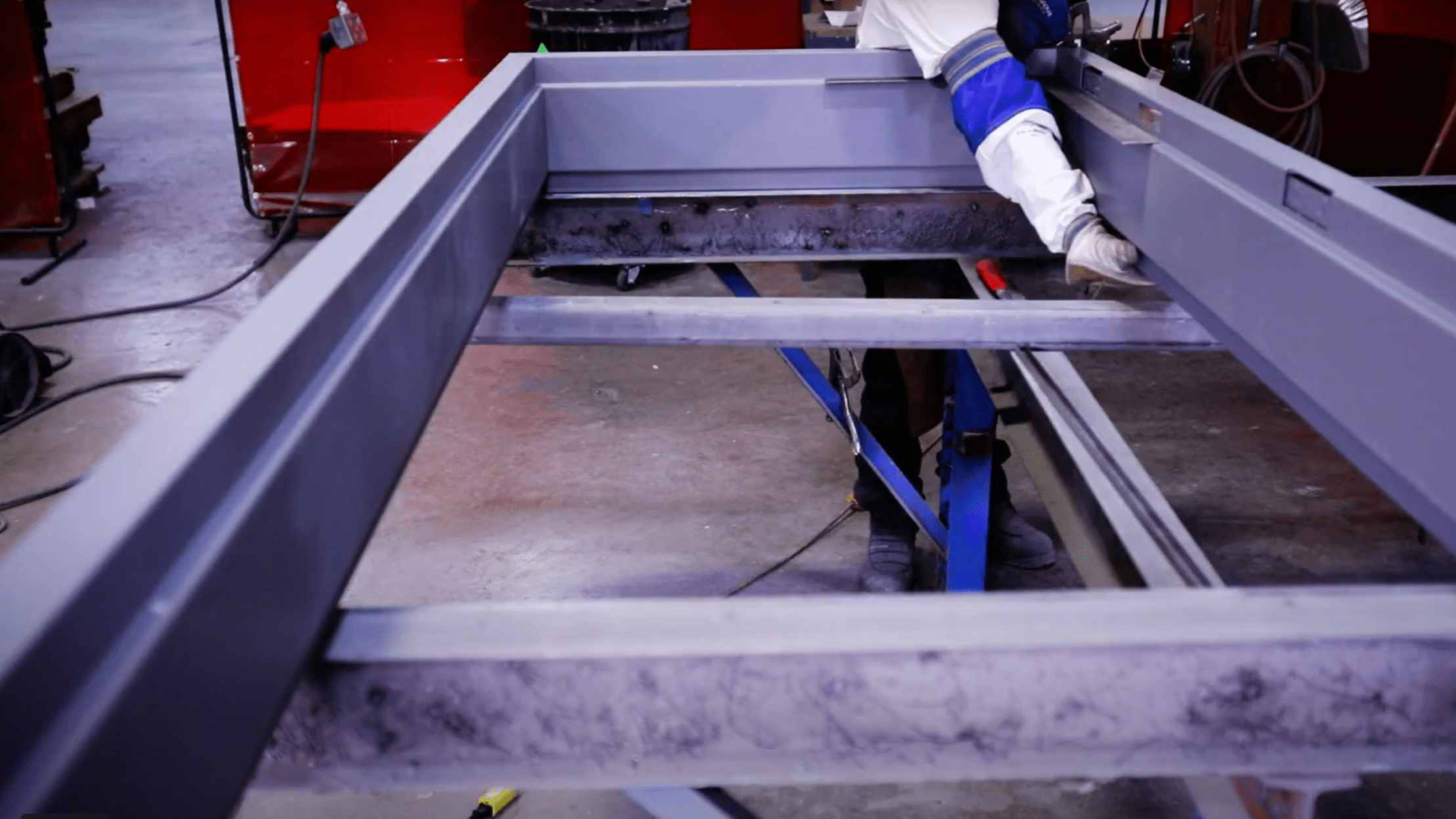

Lay the head and the two jambs down on a level work surface with the non-door side down.

Door Frame Weld Prep - Step #2

Assemble the frame by following the manufacturer’s instructions.

Door Frame Weld Prep - Step #3

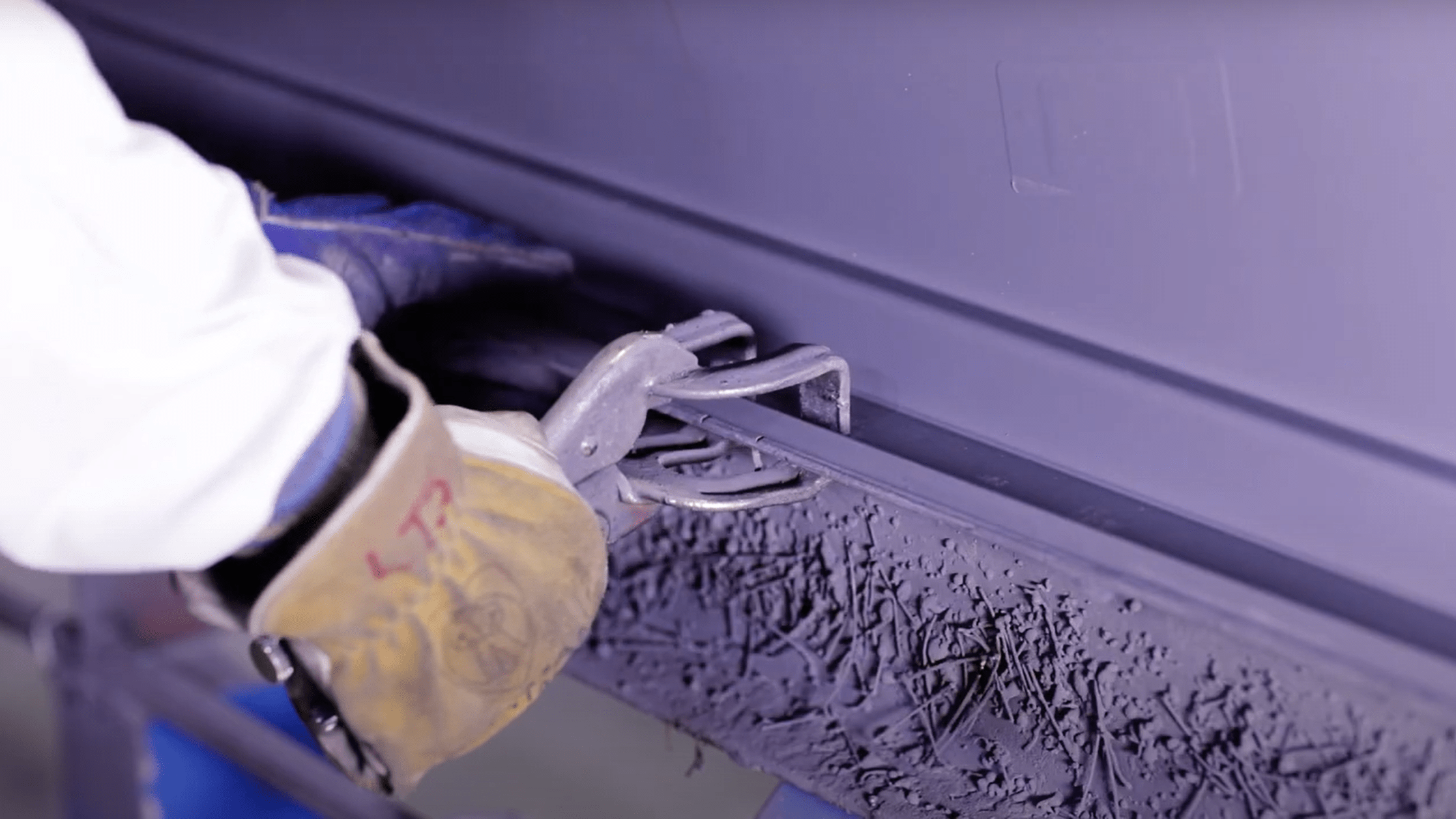

Bend the tabs on the jamb to lock the jambs to the head.

Door Frame Weld Prep - Step #4

Clamp the frame to the table for stability.

Door Frame Weld Prep - Step #5

Confirm that the frame is square and make any adjustments as needed.

Door Frame Weld Prep - Step #6

Tack weld a shipping bar into the door side of the frame to guarantee the opening width of the welded frame.

Additional Resources

Printable Manual

Three Ways to Weld Steel Door Frames

Video

Three Ways to Weld Steel Door Frames

Choose Quality Frames

Always specify SDI Certified to ensure frames that look good and are built to last. That way your frames are provided by a SDI Certified Manufacturer who has proven that their products and processes meet our standards.