The 3 Ways of Welding Steel Door Frames

This manual will guide you through the different types of welds used on 3-sided door frames. You can also reference our video for a visual demonstration of how to weld steel door frames.

Watch Video

Printable Manual

Face Weld

A face weld is when the miter joint between the head and jamb faces is welded on the exterior of the frame face. The weld will be ground, finished smooth, and prime painted so the seam does not show. The remaining elements of the frame profile such as the soffit, stops, and rabbets are not welded.

Back Weld

Back welding is weld placed on the miter of the frame where the head and jamb meet, but on the back side. This type of welding requires less grinding.

Full Profile Weld

Also specified as “fully welded” or “continuously welded”, a full profile weld is when the joints between all elements of the head and jamb profiles are completely welded. The faces and returns may be welded internally or externally. All other frame elements shall be welded internally

Preparing to Weld

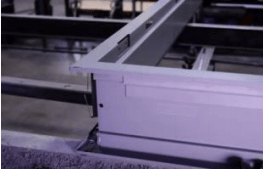

1. Properly setting up the frame before welding is critical for ensuring the finished frame is square.

2. Lay the head and the two jambs down on a level work surface with the non-door side down.

3. Assemble the frame and bend the tabs on the jamb to lock the jambs to the head. Follow the manufacturer’s instructions to determine which direction to bend the tabs. This is critical to ensure the proper door opening width.

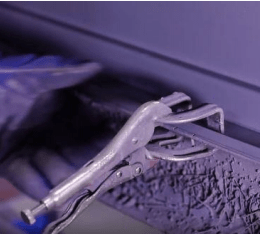

4. Clamp the frame to the table for stability. Confirm the frame is square and adjust as needed.

6. Now the frame is ready for welding. Using the minimum amount of weld necessary, apply the face weld, back weld, or full profile weld as specified.

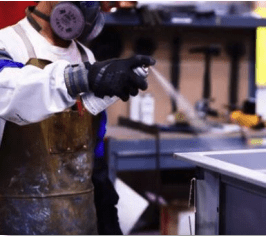

Finishing the Weld

1. Grind until the weld is level with the face of the frame.

2. File the edges smooth.

3. Finish with a DA sander.

4. The finishing process is complete, and the frame is ready to be painted.

5. After it is painted, a proper weld will give the frame a seamless appearance.

The final product has a seamless appearance