Hardware Installation – Brief Task; Lasting Effects

We all know the frustration of specifying or purchasing a product and having it not live up to expectations. Perhaps you purchased a hollow metal door and just a few years later it was sagging or the hardware was falling off. While your gut reaction may be to blame the manufacturer, the vast majority of these issues are due to the hardware installation.

While improper field installation isn’t the fault of the architect or manufacturer, their reputations are still on the line. This is why the Steel Door Institute created ANSI/SDI A250.6 – Recommended Practice for Hardware Reinforcing on Standard Steel Doors and Frames. This standard is a guide to door reinforcement and the installation of door hardware. It should be referenced by hollow metal door installers.

Why do doors need reinforcements?

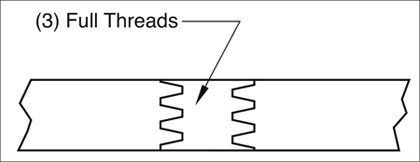

For a screw to effectively secure the hardware, it must have three threads within the door (see graphic below). But a standard 18 gauge door is only thick enough for two threads. In this situation a reinforcement—such as a plate, channel or angle—should be attached to the door to ensure the screws are properly secured.

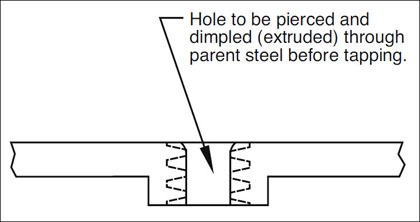

In addition to reinforcing, there is also extrusion. This is where a hole is punched in the door and an extrusion tool is pressed into the hole. This causes that part of the metal door to expand, making it wide enough for three screw threads.

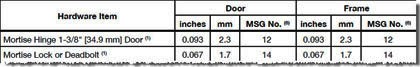

Table 1 in ANSI/SDI A250.6 (below) shows the minimum reinforcing thicknesses for commonly installed hardware. An installer should reference this table before mounting hardware. For example, if they were installing a mortise lock or deadbolt into an 18 gauge door they would see that a 14 gauge door is suggested. Therefore they would need to reinforce the door so the 18 gauge door is thick enough for—you guessed it— three threads. Failure to do so could cause performance issues as time passes.

You put a lot of time into selecting the right doors for your projects. Make sure the installers reference ANSI/SDI A250.6 to ensure your clients experience the quality of product that you specified.

SDI Course Now Offers GBCI Hour

Our AIA course Sustainability & Steel now offers one GBCI and/or HSW hour. The course is 60 minutes and can be taken online 24/7.

SDI Engages with UL Environment®

In keeping with our commitment to green building, UL Environment® has been retained to develop Product Category Rules (PCRs) for the SDI. These category rules will facilitate comprehensive Life Cycle Assessments by the member manufacturers and bring Environmental Product Declarations to the market.

Jeff Wherry, Managing Director of SDI, said, “Allowing architects, general contractors and specifiers to understand the total environmental impact of the products they select is a key mission of the SDI, and leadership in the creation of PCRs is an important step in fulfilling this mission.”