The Risks of Grouting Frames

Design professionals often wonder when a frame should be grouted. In fact, the most common word entered in the search bar on the Steel Door Institute website is “grout”. It’s understandable. There are a lot of conflicting opinions in cyberspace about the topic. We would like to take this opportunity to share with you SDI’s professional opinion on grouting.

Grouting should never be specified for drywall construction. When the grout is drying, the moisture only has two places to go. The first is into the drywall, which weakens it. This could hinder the frame’s integrity or ability to retain anchors. The other place the moisture could go is into the hardware or the bottom of the frame. And we all know what happens when metal is in a moist environment—rust.

A properly anchored frame will not be any sturdier if it is grouted. After all, drywall slip-on frames have passed fire and hose stream tests, cycle tests, and even impact tests with only anchoring.

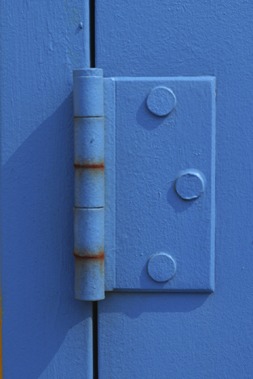

Grouting is usually not necessary for masonry construction either. To be clear, if the grouting is done properly it will not cause any issues with the frame. Unfortunately, thin pumpable slurry is often used and its excess water causes rust. There was one project where 300 doors were pumped with slurry and all of them had rusted hinges after just two months (see image). Holes were then drilled in the bottom of the frames and moisture started to seep out. So remember: Grout should always be hand troweled, never pumped.

There are a lot more risks than rewards when grouting frames. However, a properly grouted frame in masonry construction will improve the sound deadening qualities of the opening. For fire rated openings, you should verify that the grout or bituminous coating used to protect the steel frame from the corrosive effects of the grout will not negate the rating.

Not sure what’s right for your project? Check out SDI’s resources below. You are also welcome to Contact Us and we’ll be happy to advise you.

| Resources | |

|---|---|

| SDI 127I-04 | Grouting Frames in Drywall |

| ANSI/SDI A250.8 (Section 4.2 – Frame Installation) | Grouting Frames in Masonry |

| SDI 128-09 | Acoustical Performance |

Specifying Steel Doors and Frames – Let A250.8 be Your Guide

ANSI/SDI A250.8 provides recommended specifications for steel doors and frames. Originally called SDI-100, it was written more than 40 years ago. This standard has evolved alongside new testing methods, and remains a cornerstone standard in the industry to this day.

When architects specify A250.8, their doors and frames will actually meet the requirements of more than 20 other standards. It will meet the physical endurance testing of A250.4 and the hardware reinforcement guidelines of A250.6, to name just a couple.

Levels 1 through 4

A250.8 assigns the physical performance of doors from levels one through four. It is important that design professionals stipulate the doors’ level in their specifications. A level one door is “standard duty” and is designed for applications with minimal wear and tear, such as an interior office door. Level four doors are “maximum duty” and are for abusive environments, or where security is imperative.

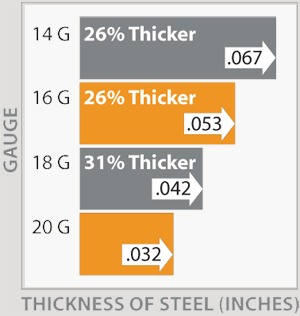

The gauge of the steel face of the door varies for these different level doors. Level one doors stipulate a 20 gauge steel face, while level four doors are 14 gauge (see graphic).

Underspecifying the performance level increases life-cycle cost since the door will have a shortened lifespan and will need to be frequently replaced. Overspecifying increases the up-front cost and results in additional expense for no added value.

A250.8 – The Gold Standard

SDI’S Technical Committee reviews the standards every five years per ANSI requirements. The most recent version is from 2008, although it is scheduled to be updated this year.

When an architect specifies to ANSI/SDI A250.8, their customer can be assured they are receiving a product that is well-constructed, tested, and evaluated to meet the specifications within that standard. Forty years after its creation, A250.8 remains the “gold standard” for hollow metal doors and frames.

One update has been made to SDI 117 – Manufacturing Tolerances for Standard Steel Doors and Frames. Section 5.4 now says, “When a suitable straightedge is laid diagonally against the door face at least 1/2″ from corners any deviation between the face and the straightedge shall not allow a 0.125″ rod or block to pass.” It used to not allow a 0.1875″ rod or block to pass.