Guideline for Specifying Steel Doors and Frames for Blast Resistance

SDI 133-22

View PDF

Table of Contents

- Introduction

- Definitions

- Blast Standard Test Methods and Design Criteria

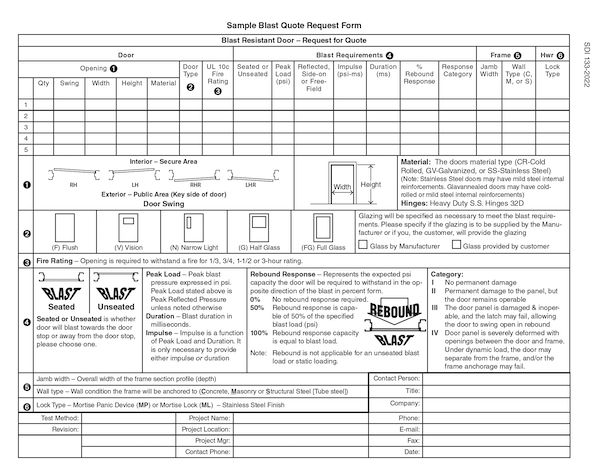

- Sample Blast Quote Request Form

1. Introduction

Blast-resistant hardening, or the structural strengthening of buildings, is one measure an owner may employ to minimize the risk to people and equipment from the hazards of accidental or intentional explosions. Many architects are finding it necessary to include blast-resistant products in new and existing construction. These products do not fall under any building code, but are required by a number of government agencies such as the Department of Defense, Veterans Affairs, Department of State, and the General Services Administration. They are backed by analysis or 3rd party test data (from an accredited lab) to show their performance level under blast load conditions. This document will serve as a guide to identify the proper criteria, and to give brief explanations of each criterion. Additional requirements, fire rating, swing, etc. are not covered.

2. Definitions

2.1 Blast Resistant Product: Assembly comprised of a door (or pair of doors) and a frame with hardware, or a glazing system that is rated to resist a specified blast peak pressure and impulse to a required performance level. Higher level doors and frames are typically sold and shipped as one unit in order to be certified by the manufacturer that it will meet the projected blast and performance requirements.

2.2 Blast Pressure: The maximum pressure to be exerted on the assembly by the blast event, typically specified as peak-reflected pressure.

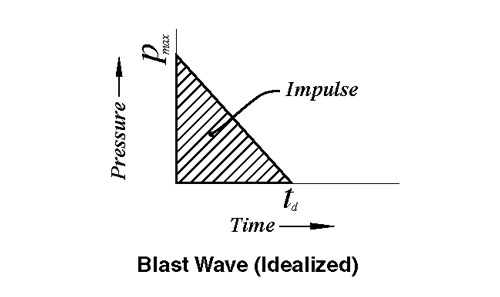

2.3 Positive Phase Impulse: The area under the curve formed by the integral of blast pressure (Pmax) vs. time (Td).

2.4 Charge Weight: The equivalent explosive weight (lbs. or kg) of TNT in the blast event. Different agencies have specific requirements for charge weight to be used. See agency specific criteria for DoD, VA, GSA, and DOS to determine required charge weight and in some cases, the required standoff distance.

2.5 Duration: The amount of time it takes the peak pressure to decay to ambient conditions (or zero), typically specified in milliseconds (ms).

2.6 Rebound: Load acting in the opposite direction of the initial blast load that may be a result of negative phase pressure loading and system response, and is typically expressed as a percentage of the initial peak blast pressure.

2.7 Stand-off Distance: The distance from the centroid of the explosive device to the specified opening or structure.

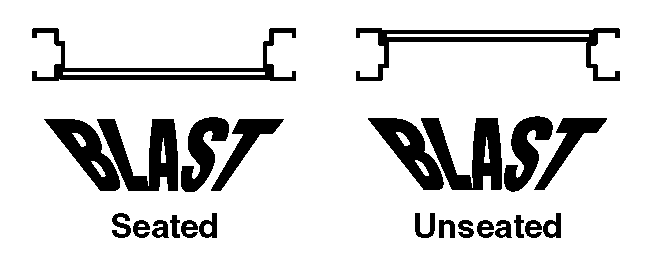

2.8 Seated/Unseated: The orientation of the door in the frame, in relation to the blast origin.

2.9 Blast Product Response & Damage Category (Also referred to as Level of Protection in the UFC): The amount of structural damage (permanent deformation) present after the blast event. With respect to a door and frame unit, the operability of the door, and whether or not the door and/or frame become detached and present a debris hazard. With respect to a glazing system, whether or not the glazing fractures, and if it presents a flying debris hazard. There are multiple standard test methods written that outline test procedures to follow to show how a blast-resistant unit will react in a blast event.

2.9.1 Paraphrased response and damage categories are given on page 2 to highlight the differences in test methods and design criteria. For the full verbiage, please reference the specified test methods and standards organization.

Blast Product Response & Damage Categories

| UFC 4-010-01 – Levels of Protection | |

|---|---|

| Below AT Standards | Severe damage and/or collapse of structure |

| Very Low | Heavy structural damage |

| Low | Moderate damage, unable to be repaired economically |

| Medium | Minor damage, able to be repaired economically |

| High | Minimal damage, no permanent deformation |

| ASTM F2247-18 – Response Categories | |

|---|---|

| Category I | No permanent deformation to the specimen is present, and the door is fully operable. |

| Category II | Measurable permanent deformation is present, but the door is operable. |

| Category III | Non-catastrophic failure, however the unit is inoperable. For unseated loads, the latching mechanism is permitted to fail, allowing the door to swing open, but the door remains supported by the hinges. |

| Category IV | The unit is severely deformed and may become detached from the hinges; however the door will not become a flying debris hazard. |

| ASTM F2912-17 – Hazard Ratings | |

|---|---|

| No Break (H1) | No fractures are present in the glazing, and no damage is visible to the unit. |

| No Hazard (H1) | The glazing has fractured, but no breakage has occurred (no debris). |

| Minimal Hazard (H2) | The glazing has fractured, and minimal fragments are present on the floor near the interior face of the glazing system (between 0 and 40 inches). |

| Very Low Hazard (H3) | The glazing has fractured and noticeable fragments are present on the floor near the interior face of the glazing system (between 40 and 120 inches). The total fragment weight cannot exceed 15 grams. |

| Low Hazard (H4) | The glazing has fractured, and fragments have fallen between 40 and 120 inches from the specimen. The witness panel, which is 120 inches away, has 25 or less perforations below 20 inches above the floor, and 10 or less perforations above 20 inches above the floor. 5 or less perforations may fully penetrate the full layered witness panel. |

| Moderate Hazard (H5) | The glazing has fractured, and fragments have fallen between 40 and 120 inches from the specimen. The witness panel has numerous perforations below the 20 inch mark above the floor, and 25 or less perforations above the 20 inch mark. 5 or less perforations may fully penetrate the full layered witness panel. |

| High Hazard | The glazing has fractured and the witness panel, which is 120 inches away, has more than 25 perforations higher than the 20 inch mark above the floor. There are more than 5 perforations that fully penetrate the full layered witness panel. |

| ASTM F2927-21 – Door Response Damage Categories | |

|---|---|

| Category I | The door specimen is unchanged and fully operable. |

| Category II | The unit has acceptable permanent deformation but it still operable. |

| Category III / S | The door remains secure during and after the loading event. The door may get lodged in the frame, and cannot be opened or passed through by a person without the use of tools, from the threat side. |

| Category III / U | The door does not remain secure after the loading event. The door can be opened or passed through without the use of the supplied hardware, and without the use of tools. The door can swing open during rebound, but remains attached to the frame at the hinges. |

| Category IV | The door can become separated from the frame and cause a flying debris hazard, or the door and frame unit may separate from the wall and cause a debris hazard. The flying debris will not go further than 3 meters. |

| Category V | The door or the door and frame unit together become dislodged and cause a flying debris hazard that will go further than 3 meters. |

3. Blast Standard Test Methods and Design Criteria

3.1 ASTM F2247-18 – Standard Test Method for Metal Doors Used in Blast Resistant Applications (Equivalent Static Load Method) – Determines ultimate static capacity. Requires further evaluation to relate to explosive charges or other dynamic loads.

3.2 ASTM F2927-21 – Standard Test Method for Door Systems Subject to Airblast Loadings – Used to determine blast capacity for a shock wave created by live explosives or a shock tube.

3.3 ASTM F2912-17 – Standard Specification for Glazing and Glazing Systems Subject to Airblast Loadings – Used to determine blast capacity from a shock wave or explosion.

3.4 ASTM F1642-17 – Standard Test Method for Glazing and Glazing Systems Subject to Airblast Loadings – The data obtained from this test method is used in ASTM F2912 to determine a hazard rating.

3.5 GSA-TS01-2003 – Standard Test Method for Glazing and Window Systems Subject to Dynamic Overpressure Loadings – The sole test protocol by which blast resistant windows and related hazard mitigation technology and products shall be evaluated for facilities under the control and responsibility of the US General Services Administration.

3.6 ASCE 2010, 2nd edition – Design of Blast Resistant Buildings in Petrochemical

3.7 PIP STC01018 – Blast Resistant Building Design Criteria

3.8 UFC 4-010-01 – Department of Defense Minimum Antiterrorism Standards for Buildings – The intent is to minimize mass casualties in buildings or portions of buildings owned, leased, privatized, or otherwise occupied, managed, or controlled by or for DoD in the event of a terrorist attack.

| Blast Requirements to be provided (Except DoD Projects) | Sample Criteria (Door) | Sample Criteria (Window) |

|---|---|---|

| Product Size (Scheduled Opening) | 3´-0˝ x 7´-0˝ Door & Frame Assy | 4´-0˝ x 4´-0˝ Window |

| Peak Reflected Pressure, Duration, & Rebound | 4psi, 100ms, 50% Rebound | 2psi, 200ms |

| Door Configuration (Seated/Unseated) | Seated in Frame | — |

| Wall Conditions | Welded to Steel Subframe | Anchored to Wall |

| Category Response | II | Very Low Hazard (H3) per ASTM F2912-17 |

| Applicable Blast Test Standard | ASTM F2927-12 | ASTM F1642-17 |

| Glazing Requirements/Thickness | No Vision Light Required | TBD by Manufacturer |

| Blast Requirements to be provided (DoD Projects) | Sample Criteria (Door) |

|---|---|

| Product Size | 3´-0˝ x 7´-0˝ |

| Charge Weight | II |

| Stand-off Distance | 250 ft |

| Level of Protection | Medium |

| UFC Revision, Revision Date, and Change Date (If Applicable) | UFC 4-010-01, 12 December 2018 |