Why Steel?

Performance Study of Steel Doors vs. Wood, Aluminum, and FRP

For architects and specifiers, the choice of door and frame materials often comes down to this: steel or something else? Steel is famously strong, but there are additional advantages to bear in mind when you ask yourself, “Why steel?”

Steel provides the best long-term value in the door and frame industry. It lasts longer, requires the fewest repairs, and is sturdier than other products. Steel’s natural strength also outperforms other materials in security, fire rating, sound reduction, vandal resistance, sanitation, and more. Hollow metal will outperform wood, aluminum, and fiberglass in demanding environments. Even when those other materials use special cores or other techniques, they are still unable to match the performance and longevity of hollow metal.

A beneficial byproduct of the strength and durability of hollow metal is the low total cost of ownership. Properly installed and maintained hollow metal doors often last 30 years or longer. As the years pass, steel doors can be inexpensively repaired in the field while softer, less durable wood and aluminum doors will have to be replaced.

Are you seduced by the so-called warmth of wood? Consider this: Today’s steel doors offer endless options for attractive appearances. Whether you are looking for a modern stainless steel appearance, a vibrant colored finish, or even a faux finish, steel’s versatility allows it to satisfy the aesthetic requirements of most projects. And don’t forget all those advantages of performance and longevity!

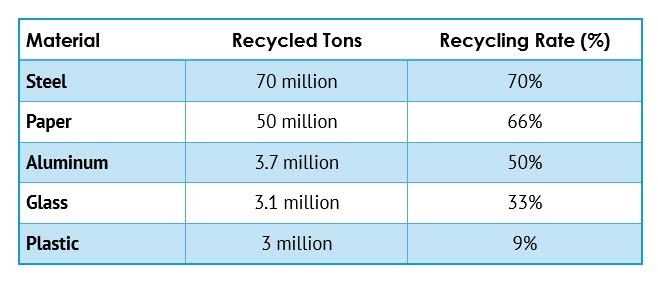

Additionally, steel doors and frames contribute to environmental sustainability. Steel is the most recycled material in North America, thanks to its magnetic properties and widespread use. It can be recycled repeatedly without losing its quality or strength, making it an eco-friendly choice that reduces costs and environmental impact for manufacturers and industries alike.

Steel Recycling Per Ton in the USA (2023) vs. Other Materials

So we encourage you to ask, “Why steel?” We think you’ll like the answer in the performance studies below.

Steel Doors vs Wood

Which perform better when comparing steel doors to wood? Find out what advantages steel doors offer over traditional wood doors.

Steel Doors vs Aluminum

Are aluminum doors preferred over hollow metal steel doors? Learn how steel doors outperform aluminum in demanding environments.

Steel Doors vs FRP

Do steel doors or fiberglass reinforced plastic (FRP) doors offer better performance? Discover the how they rate against each other in testing.