Fire Door Inspections & Checklist

Fire door assemblies are a critical part of a building’s passive fire protection system, as they help to compartmentalize the building and deter the spread of smoke, flames, and toxic gases. Over time, components of the assembly will require maintenance, adjustment, repair, or replacement. If deficiencies are not corrected, the opening protective may not function properly during a fire. Fire door inspections ensure that the fire door will function as designed and tested.

Fire Door Inspection Checklist Video

Beginning with the 2007 edition of NFPA 80 – Standard for Fire Doors and Other Opening Protectives, requirements for periodic fire door assembly inspections (FDAI) have been included in the standard. In each of the subsequent editions, the inspection requirements have been modified and expanded. When an adopted code references one of these editions of NFPA 80, the inspection criteria become enforceable by the Authority Having Jurisdiction (AHJ). The International Fire Code® 2009 edition was the first to adopt these requirements by reference to NFPA 80 2007.

Increased enforcement of the fire door inspection requirements has raised many questions about the inspection process.

Are fire door inspections required for newly-installed door assemblies?

While the adopted fire code is typically enforced for existing buildings, the adopted building code applies to buildings during the design and construction phases. The International Building Code (IBC) is the most widely-used building code in the U.S.. It references NFPA 80 for the installation of fire door assemblies: “Opening protectives required by other sections of this code shall comply with the provisions of this section and shall be installed in accordance with NFPA 80.”

Beginning with the 2013 edition, NFPA 80 requires fire doors, fire shutters, and fire window assemblies to be inspected and tested upon completion of their installation, and also upon completion of maintenance work. By reference, the 2015 edition of the IBC and subsequent editions require fire door assemblies to be inspected after they are installed, in addition to the recurring annual inspections required by the specific fire code.

Which codes state that fire door assemblies must be inspected annually?

The detailed requirements are found in NFPA 80, which is referenced by the model codes. The adopted fire code is typically enforced throughout the life of the building, so requirements for annual inspections would be found in the fire code rather than the building code. The majority of states adopt either the International Fire Code (IFC) or NFPA 1 – Fire Code which references NFPA 101 – Life Safety Code.

Always consult the fire code that has been adopted where the building is located, as some states and local jurisdictions modify the model codes. Look for the fire door inspection and maintenance requirements for fire doors and a reference to NFPA 80. For example, the IFC states: “Opening protectives in fire-resistance-rated assemblies shall be inspected and maintained in accordance with NFPA 80.” NFPA 1 includes detailed information that is consistent with NFPA 80, as well as additional guidance in Annex A. NFPA 101 references the inspection and testing requirements of NFPA 80 in Chapter 8: “Fire door assemblies shall be installed, inspected, tested, and maintained in accordance with NFPA 80.”

Which types of facilities are required to conduct annual fire door inspections?

The model codes and NFPA 80 do not differentiate between occupancy types when it comes to fire door assembly inspections; the inspection requirements apply to fire doors in all types of facilities. However, enforcement may vary locally. Health care facilities that receive funding from the Centers for Medicare and Medicaid Services (CMS) must conduct and document fire door assembly inspections, since the 2016 adoption of NFPA 101-2012.

Even if a state or local fire marshal is not widely enforcing the annual inspection requirements, it is likely that hospitals or nursing homes within that jurisdiction must perform fire door inspections due to enforcement by CMS.

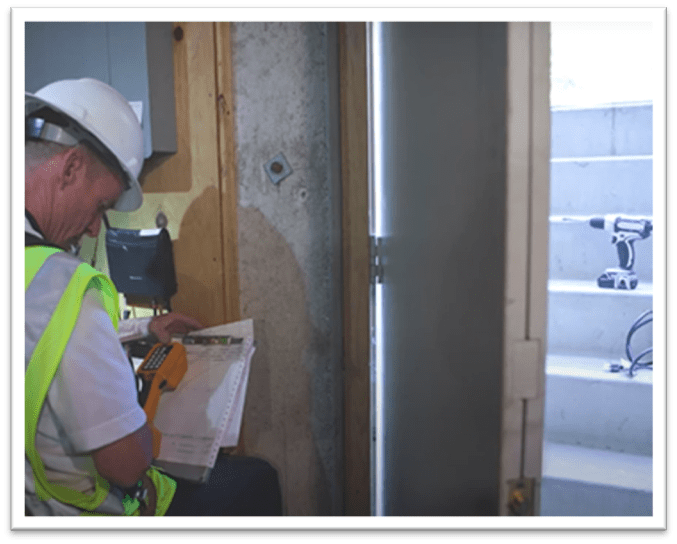

What qualifications or certifications are required for fire door inspectors?

NFPA 80 requires visual inspections and acceptance testing to be performed by a qualified person with knowledge and understanding of the types of assemblies being inspected. A qualified person is someone who has the knowledge, training, and experience to conduct inspections, and who may demonstrate their ability by possession of a degree, certification, professional standing, or skill.

Although a certification is not specifically required by NFPA 80, it may help an AHJ determine whether an inspector has the required expertise.

Do the inspection requirements apply to smoke doors?

NFPA 105 – Standard for Smoke Door Assemblies and Other Opening Protectives requires smoke door assemblies to be inspected and tested in accordance with the inspection requirements of NFPA 80. As there are various types of doors that are commonly called “smoke doors,” it is important to note that the inspection requirements apply to smoke doors that are required by code to comply with NFPA 105. For example, the IFC states, “Opening protectives in smoke barriers shall be inspected and maintained in accordance with NFPA 80 and NFPA 105.” If a “smoke door” is not required by code to comply with NFPA 105, it is not required to be inspected unless the adopted code or a local modification mandates the documented inspections.

If a labeled fire door assembly or component is installed in a location where a fire door is not required by code, is the assembly required to be inspected?

There are many circumstances where a fire door or other component with a label may be installed in a location where an opening protective is not required. A door may have been relocated from another opening, the configuration of the building may have changed, or a facility may stock labeled doors – especially labeled hollow metal doors or 20-minute wood doors where the difference in cost is minimal but the door is more versatile.

Example of a 20 Minute Fire Door Label

Example of a 90 Minute Fire Door Label

Although the presence of a label on a door or frame may cause confusion for an AHJ or fire door inspector, the model codes do not prohibit labeled components where they are not needed and do not mandate periodic inspections of these openings. There has been some controversy about this, as NFPA 101 requires life safety features that are obvious to the public to be maintained or removed if not required by code. Some AHJs considered labeled fire door assemblies as life safety features that are obvious to the public, but it appears that this was not the intent of NFPA 101. A change has been proposed for the 2021 edition of the Life Safety Code, which states, “4.6.12.4 Where a door or door frame that is not required to be fire protection-rated is equipped with a fire protection listing label, the door and the door frame shall not be required to meet NFPA 80.”

Based on this proposed change, extraneous labels could remain, without requiring the opening to be maintained as a fire door or inspected annually. However, some AHJs may continue to require these openings to be maintained and inspected as fire door assemblies as long as the labels are present. If it is determined that a labeled component is not required in a particular location, the labels can be removed or covered, depending on the policies of the AHJ. Note that once a label is removed, it can not be reattached.

What are the basic criteria that are verified during a fire door assembly inspection?

Labels are Present & Legible

If a label is missing from a component of a fire door assembly, the component may need to be properly field labeled by an authorized fire door labeling service

No Holes in the Door or Frame

NFPA 80 addresses the acceptable means for filling fastener holes; other holes must be treated as a field modification as outlined in the standard

Glazing & Glass Kit are Secure

Codes & standards require glazing in fire door assemblies to be labeled with information referencing applicable standards for impact resistance and fire testing

Door, Frame & Hardware are in Proper Working Order

Assemblies must be visually inspected from both sides, and acceptance testing includes closing the door by all means of activation

No Missing or Broken Door & Hardware Parts

If deficiencies are noted, they must be repaired/replaced “without delay” and some AHJ’s require deficiencies to be addressed within 60 days

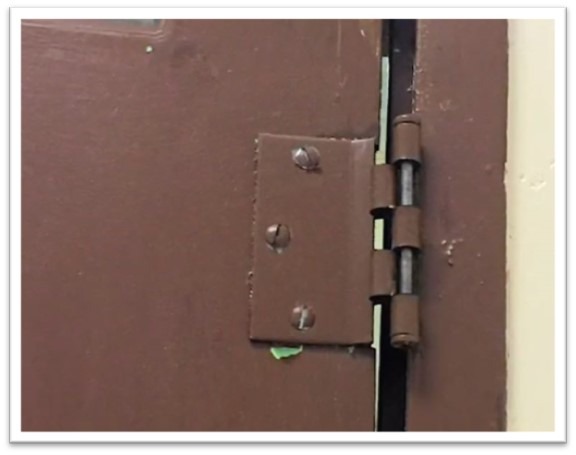

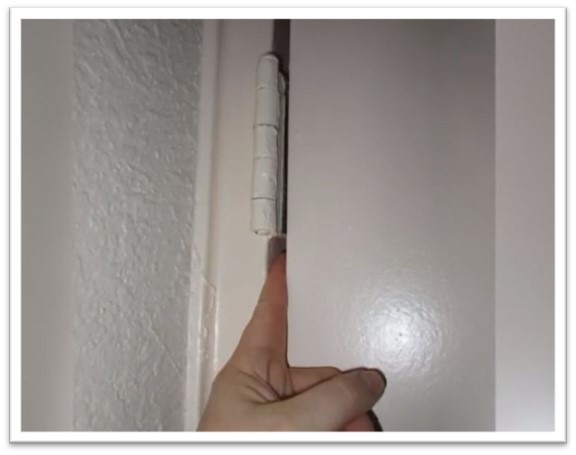

Door Clearances are within Allowable Limits

NFPA 80 applies to the installed condition of the assembly & manufacturing tolerances shouldn’t be added to maximum allowed clearance

Door Closer is Operational & Door is Self-Closing

Fire doors must be self-latching and may also be automatic-closing or power-operated, in accordance with the applicable standard

Coordinator Ensures Door Leaves Close in Proper Sequence

This code requirement applies only to pairs of fire-rated doors where one door leaf must close before the other door leaf

Door is Self-Latching in the Closed Position

This helps to ensure that the door will remain closed during a fire, to deter the spread of smoke, flames, and toxic gases

Opening is not Equipped with Auxiliary Hardware Interfering with Operation

An example of an unacceptable item would be auxiliary hardware which could prevent the door from properly opening and closing

No Field Modifications are Allowed that Will Void the Fire Label

NFPA 80 gives details on all allowable job-site preparations, and field modifications may be approved by the listing agency

Required Gasketing & Edge Seals are Present, Continuous & the Proper Type

Note that gasketing is typically required for fire doors in corridors and smoke barriers but is not required for every fire door assembly

Signage Covers less than 5% of Door Face

NFPA 80 requires signage installed with adhesive or with up to four steel or stainless-steel sheet metal screws only permitted to penetrate one side of the door and must not be installed on glazing or interfere with door operation

What is required once the inspection has been completed?

NFPA 80 details specific information that must be included in the records of all inspections and testing. This includes information about the facility, the inspector, and each fire door assembly. These records must be signed by the fire door assembly inspector and kept for review by the AHJ.

Records of acceptance tests must be retained for the life of the assembly, and inspection records must be retained for 3 years unless otherwise specified. The medium used for inspection and testing records may be paper or electronic but must be able to survive the retention period.

For specific information about fire door assembly inspection in a particular jurisdiction, refer to the adopted codes. If you have questions, consult the AHJ for assistance. Inspecting fire door assemblies after installation, after maintenance work, and annually will help to ensure that the door, frame, hardware, and glazing are installed properly and will continue to function as intended if a fire occurs.

Conclusion

Fire door inspections after installation, after maintenance work, and annually will help to ensure the door, frame, hardware, and glazing are installed properly and will continue to function as intended if a fire occurs. These requirements are in addition to maintaining an inventory of the fire protection features of the building and inspection and maintenance requirements for other life safety systems, including dampers, walls and fire stopping systems.