Should Hollow Metal Doors be Finish Painted at the Factory, by the Distributor, or in the Field?

For architects, every building project is different and requires attention to detail. While having a master spec is a great starting point, each spec should be modified for the specific project.

One decision to make is if you want the hollow metal doors to be finish painted at the factory, by the distributor, or in the field. Let’s look at these options to determine which is the best choice for your project.

Painted at the Factory

Factory finish painted doors yield the immediate advantage of a professional-grade appearance. The manufacturer typically utilizes a full-scale paint system, which may also offer a broader range of color choices and finish types. Paint used in a manufacturing facility is of the best commercial quality. This factory-grade finish is usually applied in a paint booth or paint system with environmental controls.

Custom prefinished doors, may require a minimum order quantity. One-off factory replacements may not be an option due to these minimum order requirements. Fortunately, the lead times and quality of finish are consistent and predictable.

Another consideration of factory finish painted steel doors is that the paint may get nicked in-transit and need to be touched up at the jobsite. It’s a good idea to inquire if touch up paint is provided with finish painted materials.

Painted by the Distributor

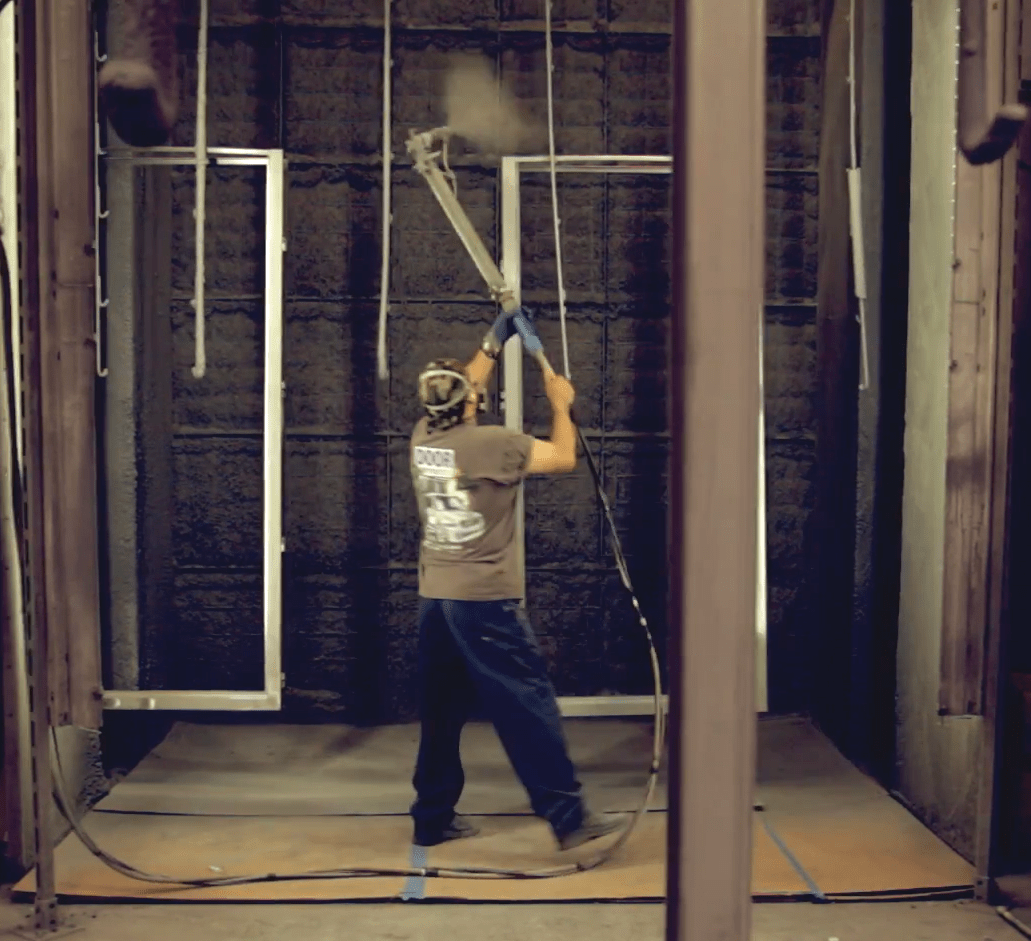

The ability of a distributor to deliver a professional-grade finish is dependent on each individual company’s process. Some have the means to employ a full-scale, high quality paint system in a controlled environment.

We spoke with the COO of one of the largest door distributors in the US, who highlighted the two most common reasons architects have distributors paint their steel doors:

2. For stock doors, of course, just have us paint them. It’s not like we’ll send those back to the manufacturer to be painted.

Painting in the Field

Painting in the field is performed by contractors with rollers and spray cans. There probably won’t be any meaningful environmental controls. Applying a professional-grade finish is problematic, and paint quality is dependent on the local supply chain. It is also one more time-sensitive task to be performed at the jobsite.

The great thing about field painting is that it is performed after transit and can cover up any potential nicks. That alone entices many architects to opt for field-painted doors.

You are also not limited by the number of doors that require finish and can apply paint as needed. But you will not be able to select higher end finishes, such as faux wood.

The Bottom Line

Generally speaking, the more flexible the process, the more variation there is in the quality of the application and finish.

No matter where your doors are finish-painted, many architects specify SDI Certified to ensure your doors are factory prime-painted per ANSI/SDI A250.10 and finish painted per ANSI/SDI A250.3. Both standards assist in meeting minimum weather and adhesion requirements, resulting in a professional appearance.