Specifying Steel Doors in K-12 Facilities:

Applications, Constructions & Finishes

The architectural process for K-12 facility designs can be envisioned and represented by models that standardize design details, such as steel doors, through a cascading refinement. The Facility Model is the starter step, establishing the initial definition model for the intended facility including purpose, function, capacity, location, building codes, and other qualifications. Scale, proportions, placements, orientation, and features of the initial Facility Model are then developed graphically into a Design Model for visualization and communication.

Design Model components are refined into product specifications that clarify construction, function, performance and other criteria of products. A parallel Code Model is applied in the process, and details are then sufficiently developed for definition in the Specification Model. Based on the refined “door and hardware schedule,” distributors quote Division 8 products to contractors, who include it in their construction quotations. It is important to note that distributors and suppliers will commonly include associated Division 8 hardware in their quotes.

Awarded contractors and suppliers in a Design/Bid project will develop product recommendations and submit for final architectural approval, finalizing product definitions for the Construction Model. Specific product brands and models to be supplied are now listed and alternates may be included for consideration. Upon approval, details of the Construction Model submittals are processed by distributors and suppliers into specific purchase orders to their manufacturing and wholesale suppliers.

Why Steel Doors for Schools?

Few doors are more prone to abuse than school doors. Students throw their backpacks against them, bang on them, kick them open, and slam them shut. That’s exactly why steel doors are a good choice for schools. They are tough as … well, steel so they can withstand the flurry of abuse.

Placing wood or aluminum doors in such a high use, high abuse area such as schools is not the most economical solution. Wood doors are easily susceptible to cracks and warping and are often irreparable once damaged. Aluminum doors, when they are repairable, usually need to be removed and sent to a workshop or repaired in the field – neither of which is ideal in a school environment, Steel doors can also be designed to fit nearly every application.

Steel’s inherent properties make it the perfect material for school doors:

✔ Strength – Steel resists dents and dings from heavy everyday use

✔ Safety – Steel doors are extremely hard to pry open when paired with the appropriate hardware

✔ Durability – Steel is long-lasting, and graffiti can be easily removed

✔ Low Maintenance – Steel doors are less likely to need repairs because they don’t crack

Choosing the Right School Doors

The biggest driver prompting schools to choose steel is longevity. For example, one Florida county requires the following for school doors:

- Windstorm-resistant exterior doors

- Steel-stiffened core

- Seamless edge

- Compliance with ANSI A250.4 Level ‘A’ criteria and tested to 1,000,000 operating cycles and 23 twist tests

Steel doors can meet these qualifications and more. Take a look at our Door Selector tool when choosing doors for K-12 facilities.

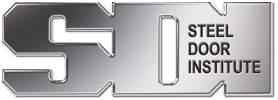

Steel Doors for K-12 Facilities

SDI’s Product Selection Guide provides recommended performance levels for common openings in schools. It also lists specialty products that are sometimes selected for those openings.

K-12 Steel Doors: What to Specify?

All of the following considerations should be taken into account when specifying steel doors for educational facilities:

- Door thickness

- Door core

- Safety requirements

- Special insulation requirements

- Gauge of metals

- Galvanized, galvannealed or cold-rolled steel

- Door edge configuration

- Top/bottom caps

- Paint requirements

Aesthetics & Finishes for School Doors

Steel doors are an integral part of school architecture, not just for their durability but also their ability to enhance the overall aesthetic appeal of the learning environment. Prefinished steel doors are often used in schools due to the endless array of colors that can be applied, resulting in a durable and visually striking door opening. As an alternative to painted finishes, wood grain steel doors offer the charm of wood while maintaining the robustness of steel, providing both elegance and strength to entrances.

Steel doors are a popular choice for many school restrooms and cafeterias due to their longevity and repairability (rather than needing to be replaced). Their easy-to-clean nature not only simplifies maintenance but also fosters a healthy environment for students. With minimal upkeep requirements, steel doors prove to be a practical and aesthetically pleasing solution for school facilities.

When it comes to gymnasiums, specifiers often opt for prefinished steel doors. These doors not only lend a customized appearance to the space but also withstand the rigorous demands of high traffic areas that involve a variety of student athletics. Their ability to showcase various paint colors and styles allows them to seamlessly integrate with the school’s colors and theme while enduring the constant wear and tear associated with gym environments.

Similarly, school classrooms rely on a diverse range of steel doors to meet their unique requirements. Wood grain steel doors, for instance, offer a perfect blend of style, aesthetics, security, and durability. By engraving the wood pattern into the hollow metal door and applying stain and a protective topcoat, manufacturers create doors that complement the classroom’s overall design while standing up to the high traffic demands of such spaces. In essence, steel doors play a vital role in not only elevating the visual appeal but also ensuring the functionality and longevity of various areas within educational institutions.

Six Types of School Door Frames

Choosing a school door frame requires weighing all of the options.

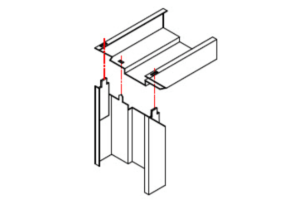

Option 1 - Steel Door Frames

Frames are units that contain single or multiple door openings without horizontal transom members and can be three or four sided. Steel door frames can have flush or rabbeted panels immediately above the doors which would be considered a transom member. They can be set up and welded, knock down, or knock down drywall construction.

(Related Article: Specifying Steel Doors & Frames)

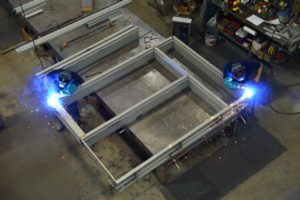

Option 2 - Welded Frames

Welded frames and elevations are commonly specified for their seamless appearance and to help ensure the frames are square. Welded frames are particularly well-suited for exterior openings and masonry walls. Though costs are higher for welded frames due to additional labor involved in the welding and finishing process, they have a superior appearance and reduce the amount of job-site labor required to assemble and properly install a frame.

Option 3 - Knock Down Frames

Knock down frames are the least expensive because they are shipped disassembled, allowing them to be tightly packed for shipping and jobsite storage. For example, a truck might be able to hold only 300 welded frames but 1,000 knock down frames.

(Related Article: Knock Down vs Welded Frames)

Option 4 - Transom Frames

Transom frames contain single or multiple door openings separated from the doors with a horizontal mullion. Transoms can be filled with glazing materials, panels or louvers. Transom frames are generally available only in set up and welded construction.

Option 5 - Sidelight Frames

Sidelight frames contain single or multiple door openings with adjacent openings (“sidelights”) for glazing materials, panels, or louvers, separated with vertical mullions. Sidelights may also incorporate transom openings, and these frames are normally available only in set up and welded construction.

Option 6 - Borrowed Light Frames

Windows are frame products that contain single or multiple openings for glazing materials only. A window that contains only one opening is also called a borrowed light or view window. Borrowed lights are available in set up and welded, knock down, or knock down drywall construction.

School Entrances & Access for Safety

Custom steel can be specified for school entrances for a variety of reasons. School entrance doors may be specified for feature such as a non-standard height, width or thickness. They can also be used to bring a unique and attractive design element to the school entryway. Door assemblies can easily be upgraded with additional safety features to protect children and teachers.

With the hustle and bustle of school activities and staff turnover, mechanical keys are sometimes lost by faculty, posing a serious security risk. Steel doors are compatible with a variety of electronic access control hardware. By using PIN codes or ID cards that are more secure than standard keys, access can be granted to unlock all necessary doors but also adjusted at any time if a card is lost or stolen.

NASFM Classroom Door Security Checklist

Protecting teachers and children while in the classroom is a high priority in all educational facilities. While protection against active shooters and violent events is a main concern, bullying and other affronts to personal safety also occur. With this in mind, the National Association of State Fire Marshals recommends the following guidelines when selecting and installing hardware on classroom doors to increase security in the classroom.

☑ The door should be lockable from inside the classroom without requiring the door to be opened.

☑ Egress from the classroom through the classroom door should be without the use of a key, a tool, special knowledge, or effort.

☑ For egress, unlatching the classroom door from inside the classroom should be accomplished with one motion.

☑ The classroom door should be lockable and unlockable from outside the classroom.

☑ Door operating hardware should be operable without tight grasping, tight pinching, or twisting of the wrist.

☑ Door hardware operable parts should be located between 34 and 48 inches above the floor.

☑ The bottom 10 inches of the “push” side of the door surface should be smooth.

☑ If the school building does not have an automatic fire sprinkler system, the classroom door and door hardware may be required to be fire-rated and the door should be self-closing and self-latching.

☑ If the door is required to be fire-rated, the door should not be modified in any way that invalidates the required fire-rating of the door and / or door hardware.

Typical steel door openings in schools are designed for safety, durability, and practicality. Many industry professionals have learned over the years that the strength and durability of steel makes it a perfect fit for school doors.

Custom steel can be specified for school entrances for a variety of reasons, and school entrance doors may be specified for function such as a non-standard height, width, or thickness. They can also be used to bring a unique and attractive design element to the school entryway, and door assemblies can easily be upgraded for additional safety and comfort at any time.

For these reasons and more, steel doors are a wise choice for K-12 school settings. Here are the SDI Certified manufacturers with distributors in all 50 states.